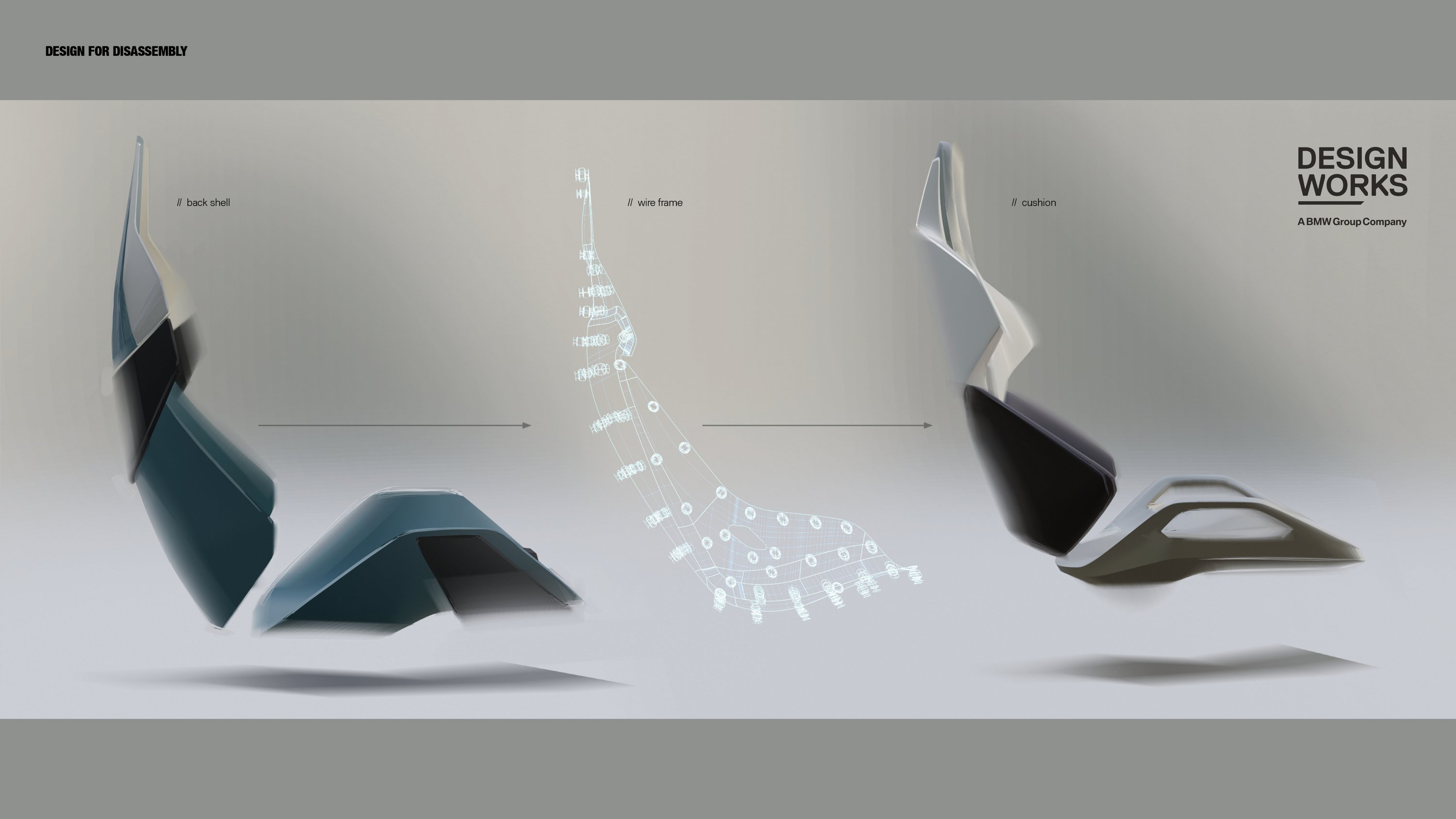

Sustainability throughout the product life cycle was a primary consideration during the development of the special seat concept recently presented by BMW.

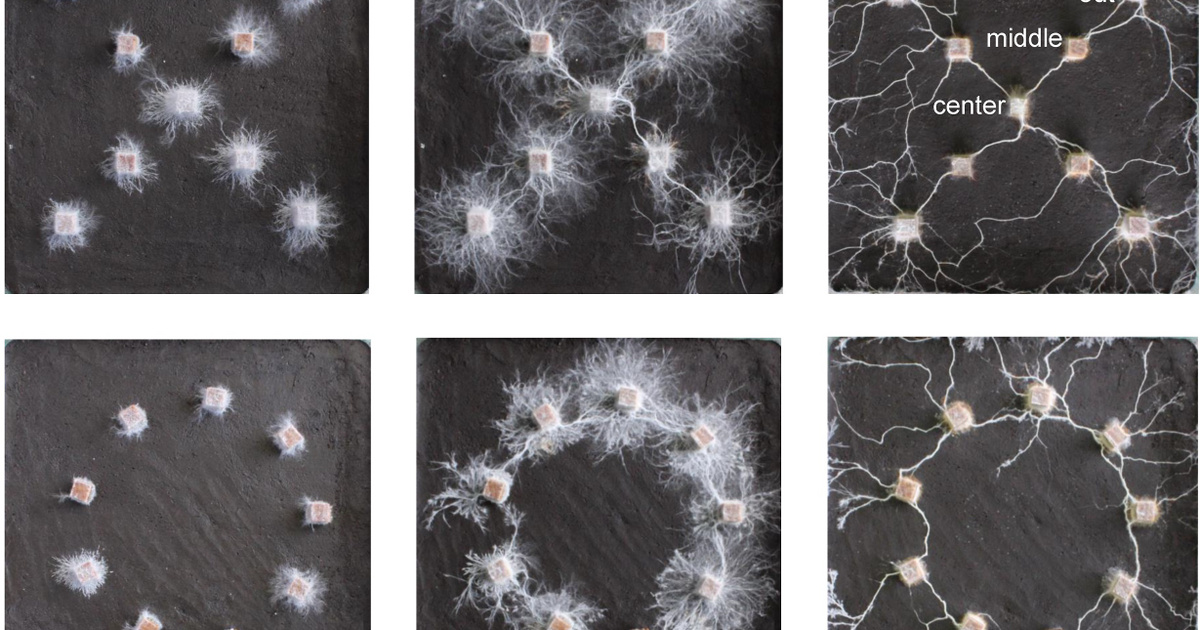

as BMW M seats with visionary material As its name suggests, the concept attracts attention primarily through its use of materials: secondary (recycled) raw materials are used in large quantities, but natural fibres, leather substitutes and algae-based polymers have also been used in its production.

At the same time, it is no coincidence how these innovative materials are used. Instead of a classic seat frame, for example, a space frame made of fibre composites, rolled by robots, supports the body. The natural raw materials of the ultra-light and extremely durable structure can be largely recycled. This also applies to the other elements of the seat, thanks to a manufacturing philosophy that tries to avoid using multiple materials within each component, thus simplifying the subsequent recycling process. Since the new structure does not require subsequent reinforcement, subsequent chemical treatment or surface treatment during production 90 percent less carbon dioxide is produced.

Series production of the BMW M Visionary Materials seat concept is not currently on the cards, but the experience gained during the development and implementation of the study could be used in the short term for series production of seats and other components.