Installing snow chains is not an innate human ability, and in most areas of Hungary you can go a lifetime without needing a traction aid. For this reason, the majority do not even train to use it, so when they encounter a situation, they cannot get through it without help.

In Korea, on the other hand, winters are said to be harsh, especially in the mountainous region, which makes up 70 percent of the peninsula, and while roads are carefully cleaned in major cities, this is not typical in villages. And mountain roads. Therefore, for riders, installing and removing snow chains is a daily practice, which is why they do it professionally, but they definitely hate it.

Therefore, researchers at the Hyundai Group (Hyundai, Kia, Genesis) have now developed a system that automatically “attaches snow chains” to the frame with the help of metal structures with shape memory.

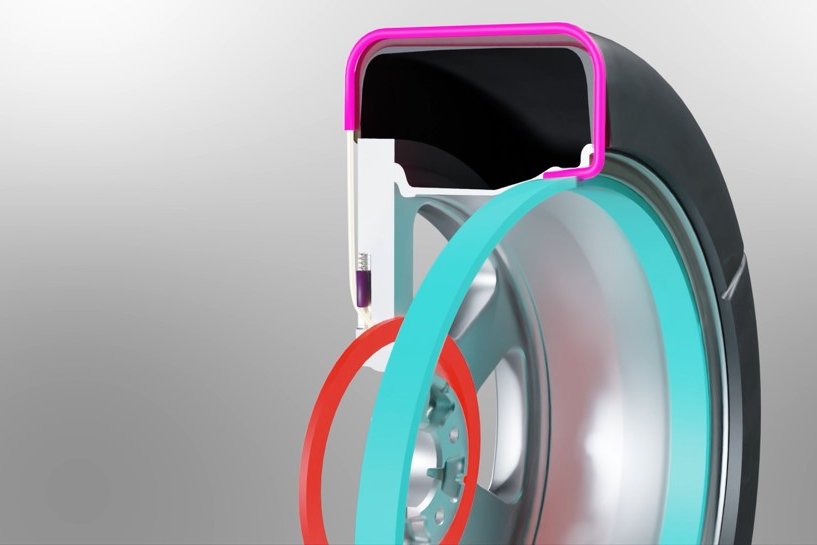

The quote is justified by the fact that the chain (more precisely, the transverse metal spokes placed at 60 degrees to the wheel) is always on the wheel, it only retracts into the transverse grooves of the tire designed for this purpose. This also means that the technology requires special rubber, which of course is not a technical disadvantage, but increases costs depending on the number of production units.

The video starts after the ad

The structure is very simple: six L-shaped metal clips are mounted diagonally on the wheel, and when activated, they change their shape: they return to the original J circumference and thus protrude from the tire surface. With another push of a button, the electrical current is cut off, and the special alloy shape is flattened again and drawn into the cavity.

The Hyundai Group has already patented this solution in Korea and the USA, and it is possible that it will eventually be introduced into series production, but for now there are still practical tests to show whether the system is effective and robust under real conditions.