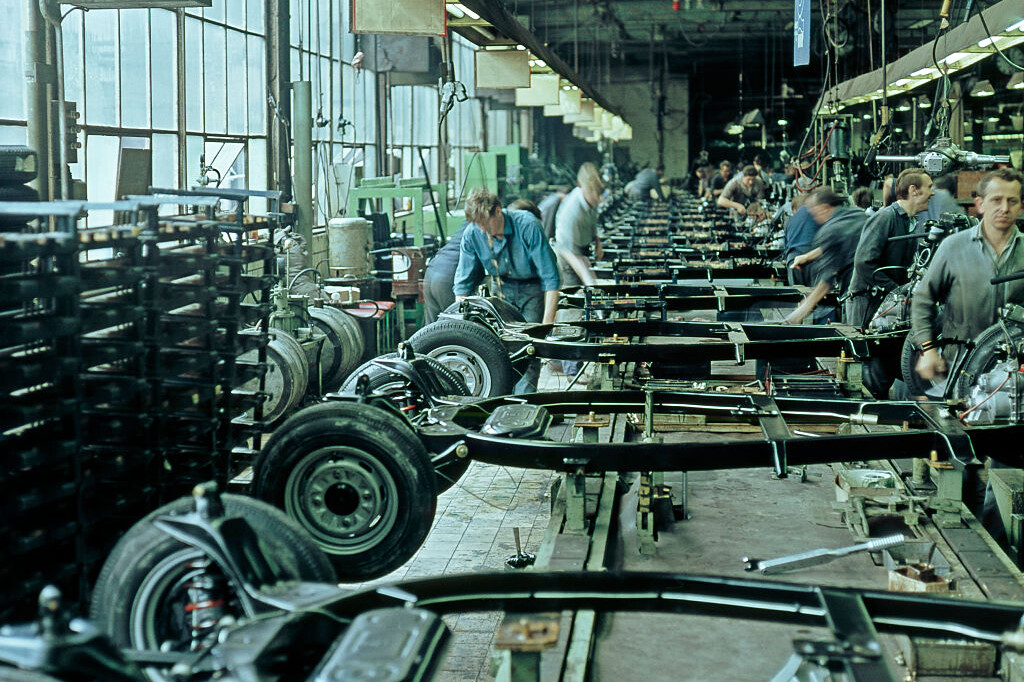

Currently, lithium-ion batteries are the standard for powering electric cars, aircraft, and smartphones, primarily due to their high performance. However, they have a major drawback: their energy density is still not high enough to meet the needs of long-distance transportation. Among other things, this prompted scientists at Chalmers University of Technology in Sweden to look for solutions that integrate the battery directly into the car's chassis, allowing energy to be stored and mechanical loads carried at the same time. Structured or structural batteries will be able to do this.

Not a thought today

The idea of structural batteries first appeared in the mid-2000s, or more precisely, when they first started building such innovative energy storage facilities. The first experiments have been linked to the US Army, but developments have also begun at various universities around the world – including Chalmers University, where materials scientist Leif Asp has been working on making the technology more efficient since 2007. But how exactly should we envision the structural battery? – It's not difficult, but it's not that simple either.

A structural battery, as the name suggests, is a battery that is not a separate unit built into the car or phone, but a structural element that makes up the car/phone itself.

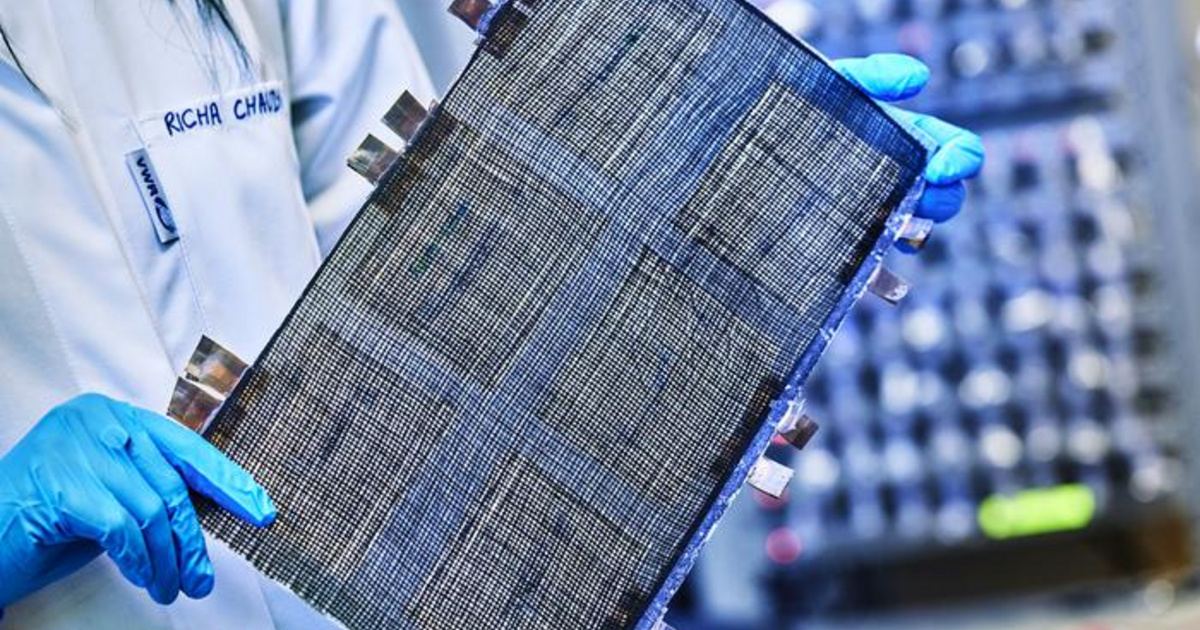

So, in fact, the frame of the car or device will be built from the battery. Previously, several prototypes of this type of battery were manufactured – their positive electrode was made of aluminum, an easily accessible material, but it was not practical from the point of view of use. That's why scientists at Chalmers University started looking for new materials – that's when they discovered that carbon fibers can store electrical energy and can also be used as electrodes in lithium-ion batteries, he points out. Eureka Alert.

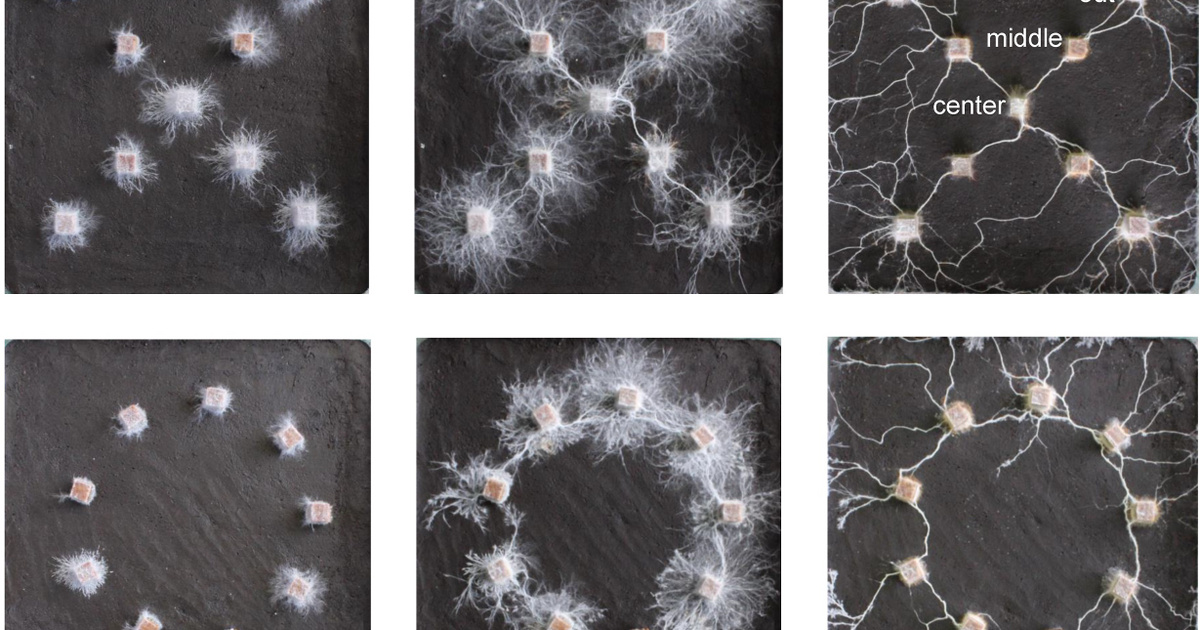

There is indeed light at the end of the tunnel

In 2021, the Swedish University research team created the first structural battery using carbon fibre, with a performance of 24 watt-hours per kilogram – and they were able to develop this further. As it is Advanced materials A study published in a scientific journal also revealed that the latest battery developed is made of a composite material and uses carbon fibers as electrodes. However, carbon fiber not only serves as the electrode in the battery, but is also used in other parts of the device, allowing the unit to be built without the use of copper or aluminium.

As a result, the weight of the new battery has been significantly reduced compared to conventional versions by approximately 20-30 percent.

The drawback is that the energy density of 30 watt-hours per kilogram achieved in the new version is still below the average performance of lithium-ion batteries, so the research team must now focus mainly on solving this problem. However, the light is already visible at the end of the tunnel, and according to predictions, in a few years we will see the technology in prototype vehicles and phones.

The iPhone has also gotten thinner, but that's not why

As Index previously reported, Apple is also working on a thinner-than-ever iPhone, but according to the latest information, that device could arrive as early as next year, so it has nothing to do with structural batteries. The phone, which is only referred to as the iPhone Air for now, will be five millimeters thinner than Apple's current 8.2 millimeters thick phones. Interestingly, even so, Apple will be far behind the imaginary platform in the competition for the thinnest phones – Honor's Magic V3, which we also tested, is just 4.35mm long, while Huawei's doubly bendable phone, the Huawei Mate XT Ultimate, just 4.35mm thick. Even thinner, it's only 3.6mm thick.

(Cover image: Part of the structural battery developed by Chalmers University of Technology. / Photo: Chalmers University of Technology / Henrik Sandcio)