NASA’s spinning detonation rocket engine—one once thought impossible—could bring the next generation of spaceflight to life.

NASA engineers have made a major breakthrough in rocket propulsion technology, and it could even change the way deep space exploration is done – says the space agency announcement. A team at NASA’s Marshall Space Flight Center in Huntsville, in collaboration with NSpace in West Lafayette, Indiana, developed and tested the Rotary Detonation Rocket Engine (RDRE), which could one day revolutionize space travel.

By the way, Japan has also tested such an engine in space in 2021. As we wrote in the article above: The Rotary Detonation Engine (RDE) first appeared as an idea at the University of Michigan in the 1950s and is based on the basic idea that compared to conventional internal combustion engines, no The fuel burns, but is detonated in a circular chamber, with the shock wave of the explosion traveling through it, thus providing the thrust while creating another explosion – meaning the process is self-sustaining until the fuel runs out. The advantage of the idea is that much more thrust can be squeezed out of much less fuel (we’re talking about a 25 percent savings), and the disadvantage is that detonation is a much more difficult process to control than combustion. The concept is also reminiscent of a pulse detonation engine (PDE), but it is even better in that in the latter the combustion chamber must be cleaned before each detonation, while in the case of the RDE we are talking about a self-sustaining, continuously running process.

Accordingly, the NASA statement states that RDRE produces more power while using less fuel than current propulsion systems, and thus may be able to transport humans to distant destinations such as the Moon and Mars. It all sounds good, and we’re probably relatively close to practicality – as you can see in the video below, RDRE’s recent hot fire test was a resounding success, and the engine was fired over a dozen times, for a total of nearly 10 minutes. gold. During these tests, RDRE achieved its primary goal of proving that its components, made with new 3D printing designs and processes, can withstand the extreme heat and pressure of blasting.

The RDRE, operating at full throttle, produced over 4,000 pounds (1,814 kg) of thrust for about a minute at an average chamber pressure of 622 pounds per square inch (63.5 bar). This is the highest compression value ever for this design and is a testament to the engine’s incredible performance. RDRE contains a NASA-developed GRCop-42 copper alloy, which, combined with a proprietary manufacturing process, allows the engine to operate in harsh conditions for longer periods without overheating. In other words, RDRE is currently a very serious promise, and with its help, both NASA and commercial spaceflight can send more payloads into deep space over time.

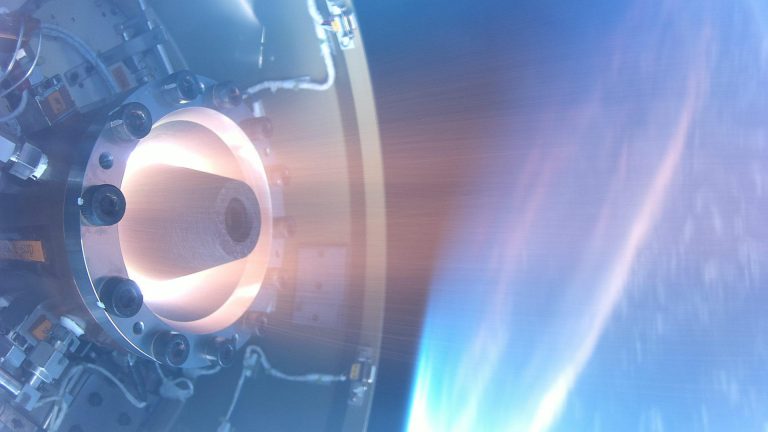

(Image: NASA)