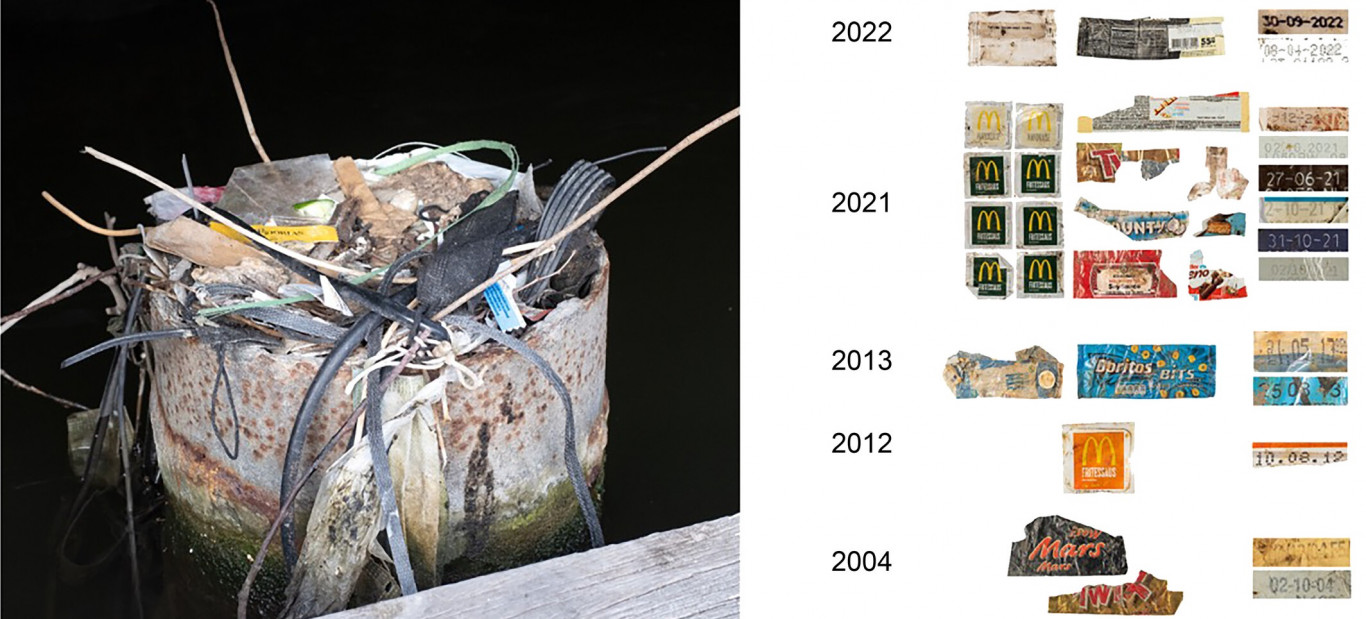

The particulate filter is an essential accessory for modern diesel cars. Since 2009, the use of parts that are harmful to the environment and the human body has become quite popular. At that time, the Euro5 emission standard was introduced, which manufacturers could only meet with a DPF (Diesel Partikelfilter).

A particulate filter is a structure used to filter out carcinogenic particles (“soot”) present in the exhaust gas of a diesel engine. The filter body is made of silicon carbide-based porous material, which is embedded in the filter housing after a catalyst. A soot trap is a maze in which at least 90 percent of the cancer-causing soot particles from diesel engines get stuck in its closed passages. Slag collects on the walls, and then the engine control gives the command to burn the particles, which is why it is called an active particulate filter.

In order to prevent premature wear of the component, it is very important to pay attention to the particulate filter regeneration cycles. If we drive a lot on the highway, the process goes almost imperceptibly, but with regular urban use at low speeds, sooner or later the filter saturation warning lamp will light up, which must be responded to as quickly as possible.

An error signal that can be resolved with some driving on the road

Flushing, done in 10 minutes, requires hotter exhaust gas, ideally 600 degrees, which the engine achieves outside the city. The process is managed by the engine control unit, and the common pressure tube injection also plays an important role. For combustion, the exhaust gas temperature must be increased: during subsequent injection into the cylinder, the temperature rises by 200-250 degrees, passing through the pre-catalyst, the remaining fuel is also sufficient, heating the gases by another 100 degrees.

The fault indication is not the same for all models, if you are not sure, the car factory manual can give you accurate information

Therefore, if a yellow warning light is flashing on your dashboard, the best thing to do is to steer towards a section of road that allows for higher speeds rather than stopping. This does not mean working on flat gas, as most filter clogging particles are produced at full load. It is recommended to carry out the cleaning cycle with a light load (with the accelerator pedal slightly depressed) and an average speed of at least 2000 revolutions, at a speed of at least 70 km / h.

If the process goes perfectly, the error signal will disappear and we can continue to use our car in normal mode. In the case of severe blockages, many companies already offer washing in various ways, which can extend the service life of the part.